Flexography is the most rapidly developing printing technique. Speed of production, high quality and versatility make it very widely used.

Flexographic printing is a way of applying low viscosity color preparations with the use of flexible printing forms on various types of materials. Flexographic technology was introduced to industry almost a century ago. Today, it is mainly used to design packaging materials, labels and polymer bags.

German entrepreneur Karl Holweg is considered the inventor of flexography. The technical basis of the method was the introduction of flexible molds made of natural rubber into the printing technology. Initially, flexography was used to reproduce lettering and images on paper products and packaging materials. As early as the 19th century, wallpaper was printed using aniline inks, and in 1912, troby was also printed using this method.

From the mid-1940s to the 1950s, flexographic printing was massively used to produce advertising materials, notebooks, and magazines. After the use of printing on film substrates of synthetic materials, postcards and packaging for bulk products also began to be printed.

The spread of flexography was facilitated by the technological nature of the method. Compared with traditional printing using metal plates, the production of molds from synthetic polymers proved easier and more convenient.

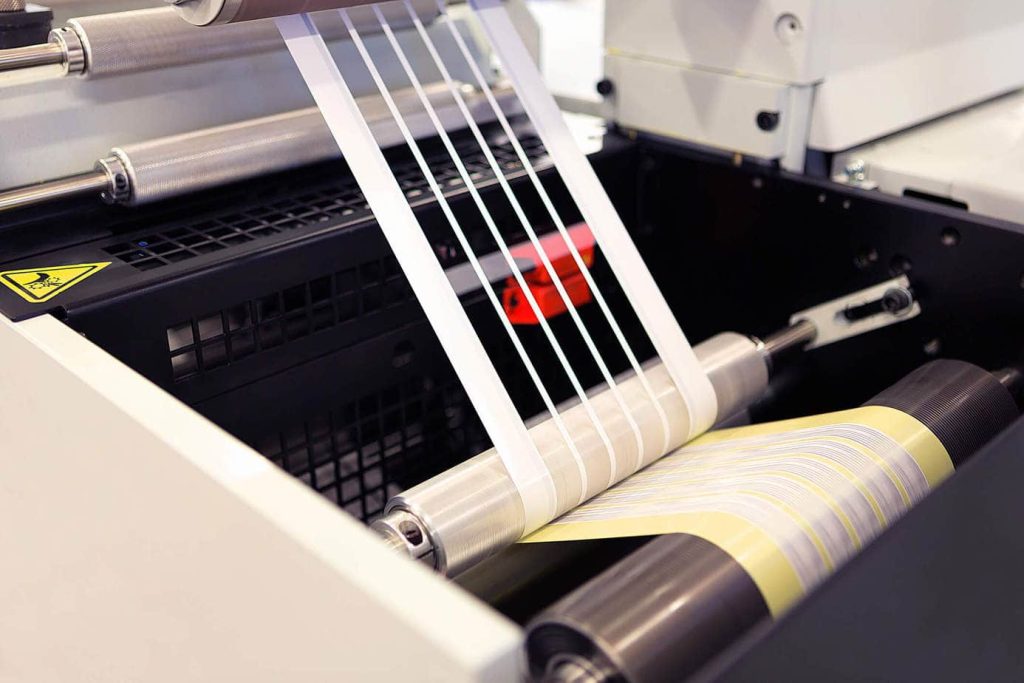

Flexographic equipment is much simpler in design than other printing units and almost all use rotary rollers. An essential component is extruded printing molds (flexographic molds), which can be made of rubber or light polymer. Flexographic printing equipment usually combines the functions of a printing machine with paper and plastic packaging equipment.

There are many brands of flexographic printing machines available in the world with different colors, dimensions of processed material and other key parameters. By design, these machines come in one of three varieties: horizontal, planetary and segmental.

Flexography is a direct printing technique. A special roller with a porous structure applies ink to the protruding areas of the mold, which form patterns and lettering. The number of pores in the roller varies and allows the amount of ink applied to be controlled.

The flexoform transfers the design directly to the substrate. One such mold can make from 1 to 5 million prints, and its flexibility allows printing on thick, flexible and irregular surfaces and the use of a wide range of materials.

The technological stages of flexographic printing are:

Flexographic printing can be performed on cardboard, plain and self-adhesive paper, film, thin plastic, polymeric materials, fabrics, etc. To achieve the desired quality and saturation, the ink must meet certain standards. Three types of inks are used in flexography.

Water-based inks. They are considered the safest and most convenient, but they cannot be used for printing on film and plastic. They are suitable for more absorbent surfaces.

Alcohol-based inks. These are inks with volatile solvents that fix by evaporation. They are used for unsaturated surfaces and synthetic materials.

UV inks. They cure when exposed to ultraviolet light and are highly resistant to the damaging effects of external factors. They are used in printing graphics and text on packaging that comes into direct contact with food.

Let’s start with the disadvantages, since there are far fewer, in fact, only one. This is the difficulty in obtaining an image with low brightness and the inability to print in small fonts.

The prevailing advantages include:

Today, flexographic printing is most widely used in the production of advertising products. It makes it possible to print labels on self-adhesive paper, corrugated cardboard, plastic and other synthetic substrates. Flexographic technology is used for printing on packaging and materials with irregular shapes and surfaces, such as milk cartons, boxes of loose products (rice, groats), plastic shopping bags. In addition, it is also increasingly used to create prints on fabrics, such as bags or T-shirts.