The printing market offers a wide variety of printing techniques for large format projects. The most popular currently is solvent printing.

Solvent printing is readily used because of its durability and low cost of production. Unfortunately, it is also highly toxic. Nevertheless, alternatives available on the market are more expensive and less durable, which is why solvent remains the most popular technique for large format printing.

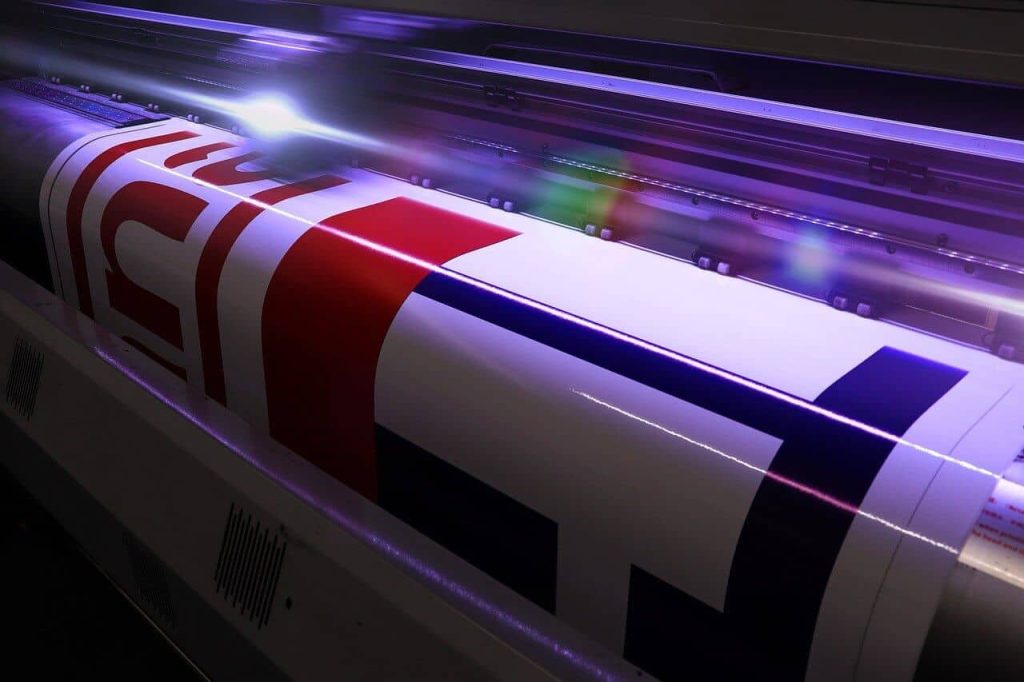

Solvent printing is a non-contact process, in which the inks penetrate heated material and form an image. Solvent inks are produced on the basis of organic solvents (cyclohexanol), which makes the print more durable and more resistant to weather conditions and mechanical damage. In addition, solvent works well on any substrate, even those that do not work with ordinary water-based inks.

The type of solvent printing depends on the amount of solvent used in the ink base. Based on this, you can distinguish between:

Solvent printing is most often used to create large-format and medium-format outdoor advertisements, and in the case of eco-solvent also indoor, such as:

This is not a closed list of course, but it clearly shows that the solvent technique will work for many different projects and is suitable for work on virtually all surfaces.

Solvent has a number of advantages, the most notable of which is its durability. It is characterized by:

The above mentioned factors make solvent an ideal choice for projects that will be exposed to long-term effects of unfavorable external factors such as sunlight or temperature changes. Additionally it is relatively cheap.

With such obvious advantages it has few disadvantages. One of them is the lack of precision, which, however, is not a big problem with prints viewed rather from a distance. A bigger disadvantage is the toxicity, mentioned at the beginning, of the solvents that form the basis for solvent ink. For this reason, solvent is harmful to both people and the environment, it is also not suitable for indoor use because it gives off an unpleasant irritating smell. Also, the process of producing solvent inks itself is not indifferent to the environment.

Of course, if you don’t want or can’t use hard or mild solvent printing, you can reach for available alternatives – the already mentioned eco-solvent or latex printing.

Ecosolvent is completely harmless because it is based on lactic acid instead of toxic cyclohexanol. It also does not emit an unpleasant smell, so it can be used indoors. Additionally, it is the only one of the solvent prints that allows precise printing in high quality, so it will also work well for smaller projects. Unfortunately, eco-solvent is less durable and also more expensive. It is also not suitable for working with every surface

Latex printing is based on inks consisting of water (70%) and pigmented synthetic resin and organic solvent. During printing, the ink forms a thin film on the surface of the material and when the water evaporates under high temperature, the pigment remains on the surface. Latex printing is more durable than eco-solvent printing, but also the most expensive of all available options. However, it allows for precise designs and is safe for the environment and human health.