When choosing a marking method, many parameters should be taken into account. The most important of these is the engraved material, the required marking precision, the production speed, and the shape of the engraved object. Thus, in order to determine which method will be the best, we need to analyze several factors.

Using a mechanical method, almost anything can be engraved, unlike lasers which we cannot use to mark all materials. Not all plastics are suitable for laser engraving with a single device, some materials require a YAG laser and others a CO2 laser.

On the other hand, lasers are more controllable – making them suitable for delicate materials that would be damaged if stamped or cut too deeply and aggressively.

Lasers allow us to create vertical edges, while mechanical engraving allows us to engrave both vertical and V-shaped patterns, which are very common in decorative engraving. With lasers, however, we can control the engraving, which cannot be said of the mechanical method.

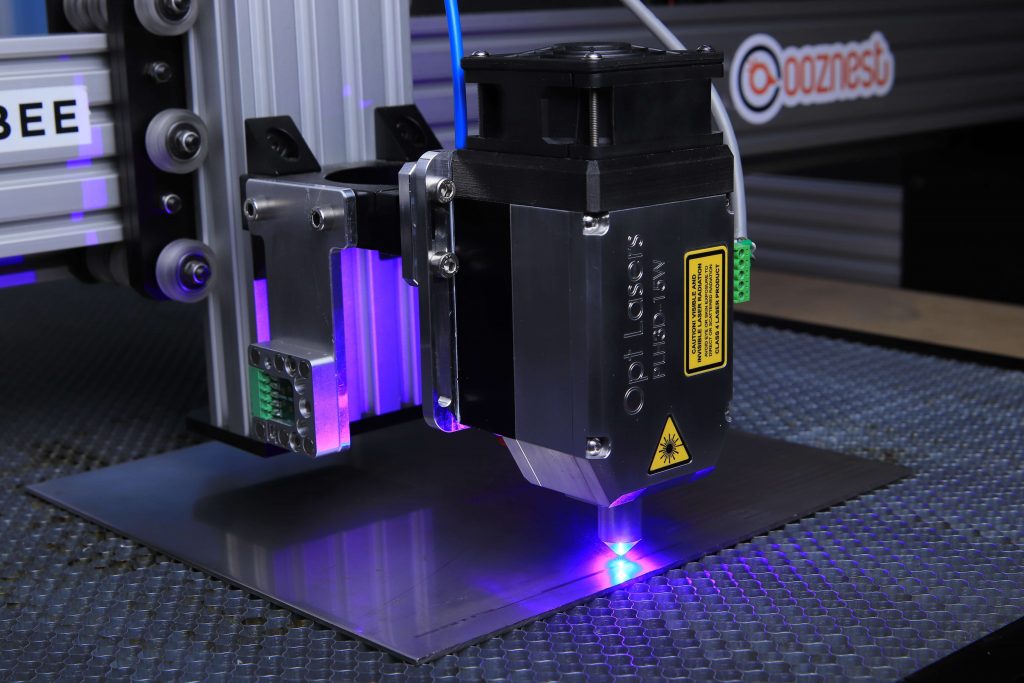

Because lasers cut with light with incredible precision, they are much more perfect in this respect than traditional cutting, stamping or punching

Lasers are extremely programmable, which means they can be configured extremely quickly to achieve the parameters you want. For this reason, they are the preferred method for engraving characters such as serial numbers or bar codes.

Decorative fonts, serif fonts, photos, logos or graphics; these are just some of the engravings that can be achieved with a laser, which would be much more difficult, expensive or simply impossible with diamond cutting, micro-percussion or embossing. Lasers are also better suited for markings that change, such as logos.

Laser engraving is usually cheaper for industrial applications, mainly because of its flexibility and programming

The best way to compare rotary laser engraving with more traditional methods – engraving is based on your own product and production requirements. Nevertheless, laser engraving is currently preferred due to its lower price and flexibility in parameter selection.